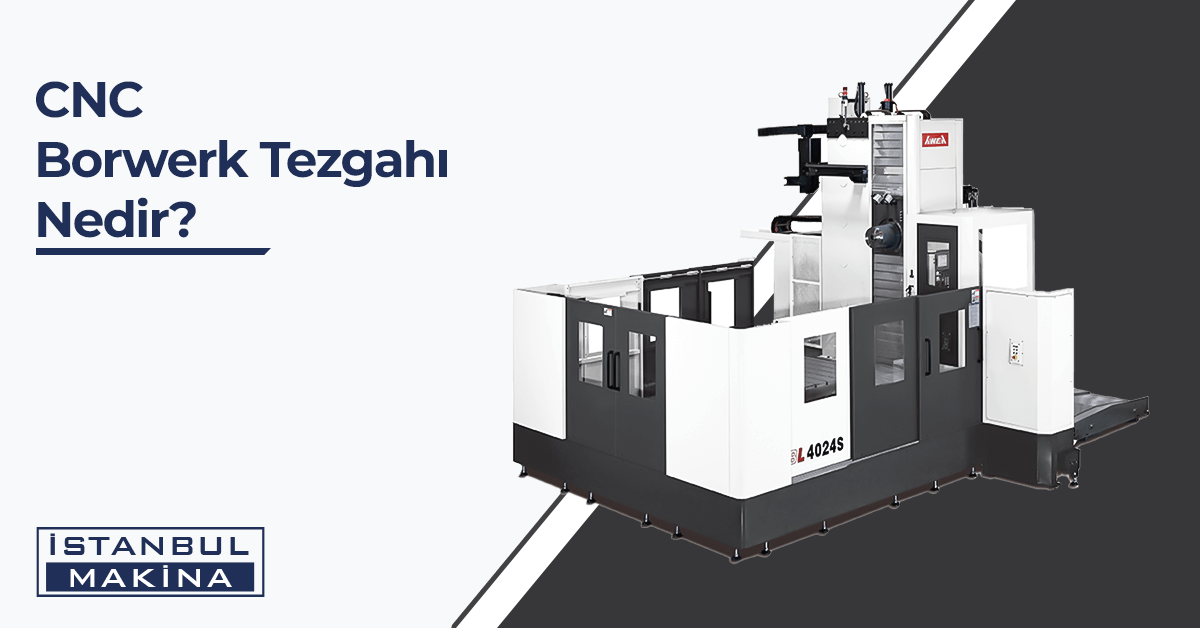

WHAT ARE CNC BORE MACHINES?

CNC bore machine tools refer to large-scale machine tools used for machining metal, wood or other materials using computerised numerical control (CNC) technology. The term "bore" comes from German and means "hole drilling". These machines are usually designed for machining large parts and are used in operations requiring high precision.

CNC bore machines can perform operations such as machining the surfaces of the workpiece, drilling holes, threading, milling. These machines use a moving cutting tool that is guided by a CNC control unit. This control unit uses a computer programme that determines the cutting path and speed required for machining the workpiece.

CNC bore machines are commonly used in automotive, aerospace, defence, shipbuilding and other large-scale manufacturing industries. They play an important role in the production of large and complex parts that require precision machining. These machines can improve manufacturing processes by providing high productivity, repeatability and precision.

WHAT ARE CNC BORE MACHINES FOR?

CNC bore machines are used in the production and machining of various large-scale workpieces. Their main functions are:

Drilling: It is used for drilling holes in large parts. The drilling process allows to create holes on the workpiece in the desired dimensions.

Milling

Milling is used to remove and shape material from the surface of the workpiece. This is usually done to determine the contours, surface roughness or other features of the workpiece.

Threading

CNC bore machines can be used to create threads on workpieces. This process enables the necessary threads to be formed for screws, bolts or threaded fasteners.

Surface Treatment

It is used for smoothing, profiling or other machining of workpiece surfaces. This enables parts to be made to the required dimensions and tolerances.

Precision Machining

CNC bore machines are ideal for processes requiring high precision. They are especially used for precision machining of large and complex parts.

These processes play an important role in the production of parts that are often used in the automotive, aerospace, defence, shipbuilding and other large-scale manufacturing industries. CNC bore machines improve manufacturing processes by enabling workpieces to be produced with high precision and repeatability.

WHAT ARE THE FEATURES OF CNC BORE MACHINES?

CNC bore machines have a number of features, including

Large Workpiece Processing Capacity

CNC bore machines are usually capable of machining large and complex workpieces. This is ideal for machining industrial-scale parts.

High Sensitivity

These machines are designed for operations requiring high precision. Thanks to CNC control systems, operations can be performed on workpieces with very fine tolerances.

Multi-axis Machining Capability

CNC bore machines usually have the ability to move in multiple axes. This is important for versatile machining and the production of complex parts.

Automatic Vehicle Change System

These machines are usually equipped with automatic tool change systems. These systems enable the quick and easy change of different inserts for different operations.

CNC Control System

CNC bore machine tools are driven by computerised numerical control (CNC) systems. This allows processes to be programmed and controlled, which ensures repeatability and precision.

Strong Processing Capability

CNC bore machines are usually equipped with large motors and high-power cutters, which enables efficient machining of various materials.

Efficiency and Automation

CNC bore machines increase productivity by increasing automation in production processes. This enables workpieces to be produced faster and more consistently.

These features ensure that CNC bore machines are generally preferred for the production of large and complex parts. These machines play an important role in industrial manufacturing processes and are used in many different industries.

WHAT ARE THE TYPES OF CNC BORE MACHINE?

Types of CNC bore machines may vary according to their intended use, processing capacity and technical specifications.

Vertical CNC Bore Machines

This type of machine tools process the workpiece on a vertical axis. They are ideal for machining large and high workpieces.

Horizontal CNC Bore Machines

This type of machine tools process the workpiece on a horizontal axis. They are used for machining large and long parts and generally have a higher cutting capacity.

Gantry Type CNC Bore Machines

Gantry-type machines are used for machining large-sized parts. They are equipped with a horizontal cutting head that moves between two vertical arms.

Table Type CNC Bore Machines

This type of machine utilises a flat table to support the workpiece. They are generally preferred when the workpiece does not need to be rotated.

CNC Bore Machines with Moving Columns

This type of machine tool has a design in which the column moves. This enables larger parts to be machined and can change the position of the workpiece with greater flexibility.

Gantry-Horizontal CNC Bore Machines

This type combines the features of gantry type and horizontal type machines. They are used for machining large-sized parts and have high cutting capacity.

Among these varieties, each is designed to meet specific application requirements. The selection is made based on factors such as workpiece size, machining requirements and production process.

IS IT DIFFICULT TO USE CNC BORE MACHINES?

Using CNC bore machine tools can have a definite learning curve, but is usually not as complex as learning a specialised skill set. Here are some aspects of using CNC bore machine tools:

Education and Experience

To use CNC bore machines effectively, it is important to receive training and gain experience. This training can often be provided through vocational schools, technical training centres or courses offered by machine tool manufacturers.

Programming Knowledge

In order to use CNC machines, it is usually necessary to learn how to create the appropriate NC (numerical control) codes for the machine using computer-aided design (CAD) and computer-aided manufacturing (CAM) software.

Safety Information

It is important to know and apply safety precautions when using CNC bore machines. This includes elements such as setting up the machine correctly and safely, handling the workpiece and using cutting tools.

Bench Maintenance

CNC bore machines require periodic maintenance for proper operation. This includes cleaning and lubricating the parts of the machine, replacing or adjusting parts when necessary.

Problem Solving Skills

As with any manufacturing process, unexpected problems can be encountered when using CNC bore machines. In this case, the skills to identify and solve problems are important.

Operating CNC bore machines, despite their advanced technology, is a learnable skill set for many users. With proper training, experience and careful study, users can use these machines effectively.

HOW DO CNC BORE MACHINES WORK?

CNC bore machines operate using computerised numerical control (CNC) technology. Here is an explanation of how CNC bore machines work in general:

Design and Programming

The first step is to create the design of the workpiece. This is done using CAD (computer-aided design) software. Once the design is completed, the NC (numerical control) codes required for machining the workpiece are generated using CAM (computer aided manufacturing) software.

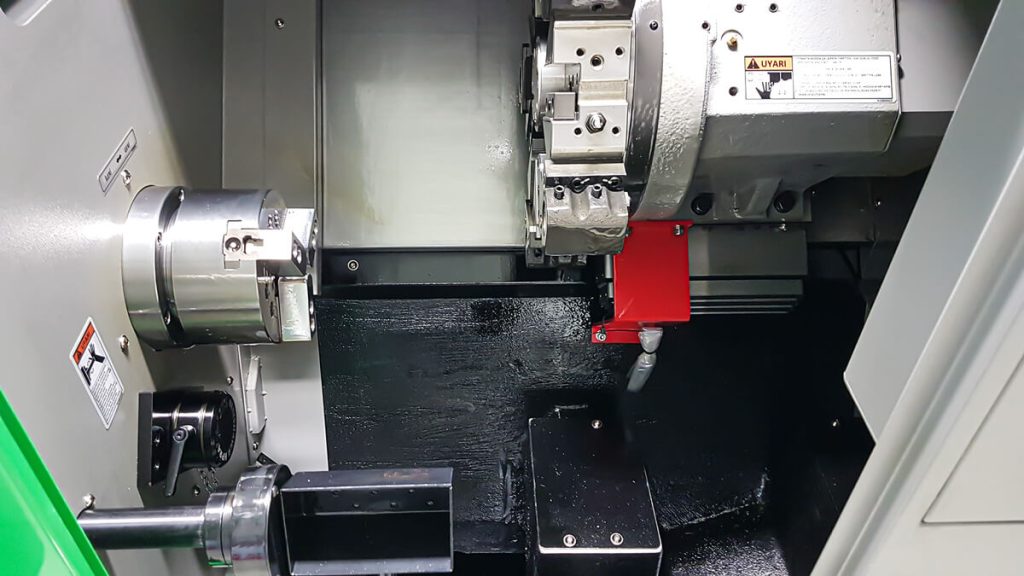

Workbench Preparation

The CNC bore machine is prepared with a table or vice for fixing the workpiece. The selection and fitting of the cutting tools required for machining is also done at this stage.

Programme Installation

NC codes are loaded into a control computer and made readable by the machine tool. These codes contain the cutting path, speed and other parameters required for machining the workpiece.

Workpiece Processing

The CNC bore machine processes the workpiece according to the cutting paths determined by the CNC control system. The cutting tool performs the desired operations on the workpiece, these operations can often include operations such as drilling, milling, threading.

Automatic Control

The CNC control system ensures that the cutting tool moves at the correct position and speed. Sensors and measuring instruments check the dimensions and position of the workpiece and, if necessary, correct the movement of the cutting tool.

Finishing and Quality Control

After machining is completed, the workpiece is inspected for quality control. CNC bore machines ensure that the workpieces conform to the specified tolerances by providing high precision and repeatability.

CNC bore machines automate the machining process by operating under computer control, resulting in faster, more consistent and more precise results. These machines play an important role in industrial manufacturing processes and are used in many different industries.

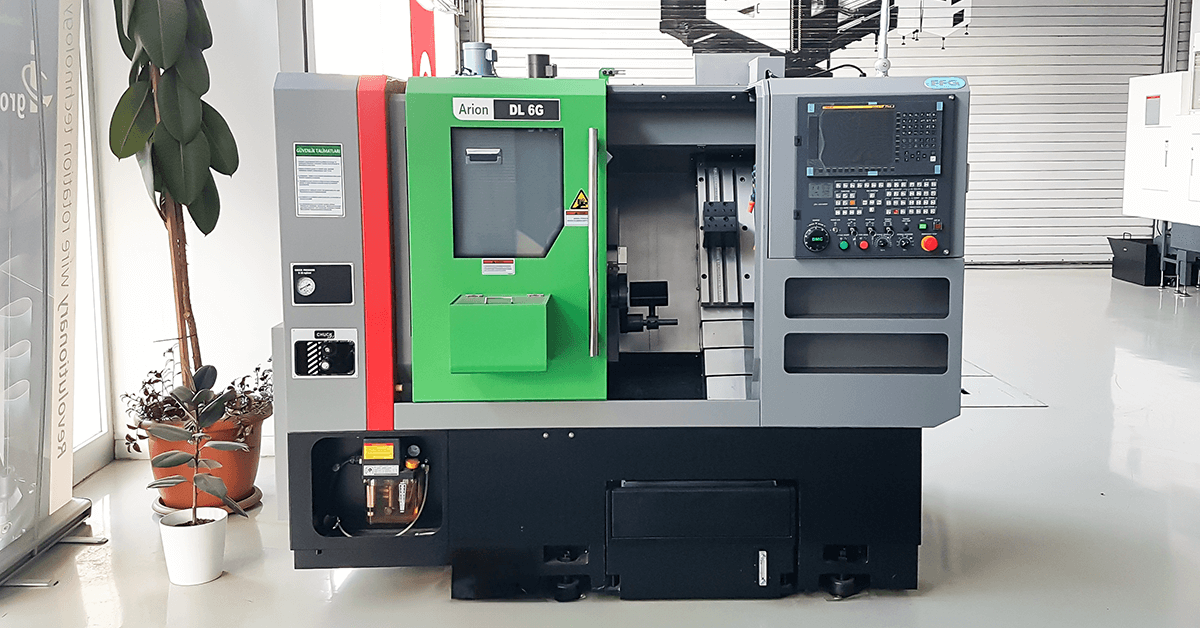

CNC lathes automate the machining process, ensuring high precision and repeatability. This increases efficiency in production processes and reduces the possibility of errors.

CNC lathes automate the machining process, ensuring high precision and repeatability. This increases efficiency in production processes and reduces the possibility of errors. Computer Controlled Processing

Computer Controlled Processing