Content Headings

WHAT IS CNC LATHE MACHINE

CNC lathe machineis a computer controlled lathe. The abbreviation "CNC" stands for "Computer Numerical Control". Such machines are controlled by a computer to cut and shape the part to be machined.

Conventional lathes are mechanical machines where the operator manually controls the cutting and shaping of the workpiece. CNC lathes, however, automate the process through a computer programme that contains a set of instructions and codes. This programme includes the dimensions of the part to be machined, its shape and other details to be machined.

CNC lathes have a wide range of uses in the processing of metal, wood, plastic and other materials. They are used for the production of precision parts and can perform high tolerance operations. These machines are widely used in mass production and in the production of special parts.

HOW DOES A CNC LATHE WORK?

CNC lathes operate under the control of a computer and generally follow the following steps:

Part Design

The first step is to create a design of the part to be machined or import it using a CAD (Computer Aided Design) programme. This design includes the dimensions, shape and other important features of the part to be machined.

CNC Programming

The design is translated into a set of instructions and codes using a CNC programming software. These codes specify the path, depth of cut, cutting speed and other machining parameters to be followed during the machining of the part.

Workbench Preparation

The material to be machined is placed and fixed on the CNC lathe. The correct positioning of the workpiece and other settings of the machine are made via the control panel of the machine or computer.

Installing the Program

The prepared CNC programme is loaded to the control unit of the machine.

Start Processing

The CNC controller starts the machining process by running the loaded programme. This allows the cutting tool to follow its path on the workpiece, perform cutting operations and create the desired part shape.

Workpiece Inspection

The CNC lathe automatically controls the depth of cut, cutting speed and other parameters during machining. The operator can monitor the progress of the process and intervene when necessary.

Finishing and Quality Control

After machining is completed, the workpiece is removed and further processing can be carried out if necessary. The workpiece is then subjected to quality control and corrections are made if necessary.

CNC lathes automate the machining process, ensuring high precision and repeatability. This increases efficiency in production processes and reduces the possibility of errors.

CNC lathes automate the machining process, ensuring high precision and repeatability. This increases efficiency in production processes and reduces the possibility of errors.

WHAT ARE THE FEATURES OF CNC LATHE?

CNC lathes have a range of features and can differ in various areas such as machining capabilities, control systems, precision levels and functionality.

Computer Controlled Processing

Computer Controlled Processing

CNC lathes perform machining operations under computer control. This allows precise control of the cutting path, speed and other parameters during the process.

Multi-axis Machining

Most CNC lathes have the ability to move on multiple axes. This enables more complex parts to be machined.

Automatic Tool Change

Some CNC lathes have the ability to automatically change different cutting tools. This speeds up the machining process and increases process flexibility.

High Sensitivity

CNC lathes can generally provide high precision. This enables them to be used in the production of parts with low tolerances.

Programmability

CNC lathes can be programmed to machine different workpieces. This allows a single machine to be used in the production of various parts.

Efficiency and Repeatability

Automated machining and programmability provide repeatability while increasing the productivity of CNC lathes.

Ease of Integration

CNC lathes can be easily integrated with other production equipment. This allows the production process to be made more efficient.

Workpiece Routing

Some CNC lathes have a switching or indexing feature where the workpiece rotates, allowing more complex parts to be machined.

These features make CNC lathes an overall flexible, efficient and precise machining solution. Each feature is favoured according to specific production needs and usage scenarios.

WHAT ARE THE APPLICATION AREAS OF CNC LATHE?

CNC lathes have a wide range of uses in various industrial application areas. Here are some application areas where CNC lathes are widely used:

Automotive Industry

The automotive industry widely uses CNC lathes for the production of engine parts, transmission components, steering parts and other important parts.

Aerospace Industry

In the aerospace industry, CNC lathes are used to manufacture aluminium, titanium and other light alloy parts with complex geometries. These parts can be airframes, engine parts, landing gear and other critical components.

Medical Devices

The medical device industry uses CNC lathes for the production of prostheses, implants, surgical instruments and other medical devices. Since these parts need to be precise and of high quality, CNC lathes are preferred.

Defence Industry

The defence industry uses CNC lathes for the production of military vehicles, weapon systems and other defence equipment. These parts can be complex geometry parts made of high-strength materials.

Energy Sector

In the energy sector, CNC lathes are used for the production of parts for power generation equipment, oil and gas industry equipment, wind turbines and other energy facilities.

Machine Manufacturing

General machine manufacturing uses CNC lathes for the production of various parts. These parts can be used in industrial machines, tools and other machine parts.

Electronics Industry

The electronics industry uses CNC lathes for the production of precision components. This can be electronic circuit boards, connectors, sensors and other electronic components.

CNC lathes are generally preferred for the production of parts with complex geometry, high precision and repeatability. Therefore, they are widely used in many industries such as the industries mentioned above.

WHAT SHOULD BE CONSIDERED WHEN BUYING A CNC LATHE?

There are many factors to consider when purchasing a CNC lathe. Here are some of these factors:

Processing Capacity

Depending on the part dimensions and complexity you need, the machining capacity of the lathe is important. This includes the largest diameter, length and machining capabilities of the lathe that can be machined.

Sensitivity

It is important to select a lathe that will provide the precision to the tolerances required by your workpieces. Precision often depends on the structural rigidity of the machine, the control system and other factors.

Material Diversity

Assess the lathe's capabilities for machining various materials, taking into account the materials you plan to work with. Some lathes can only machine certain materials such as metal, plastic or wood, while others have a wider range of materials.

Control System

The control system of the lathe manages the machining process and plays an important role in part production. A good control system ensures that machining parameters are set precisely and parts are produced with high quality.

Automation Capabilities

Automation can increase production efficiency and reduce labour costs. Evaluate the automation capabilities of the lathe, such as automatic tool changing, part loading/unloading systems, and other automated features.

Service and Support

The service and support offered by the lathe supplier is important. Good technical support ensures that problems are solved quickly and that the lathe runs efficiently.

Budget

Of course, your budget is also important. Choosing a lathe that fits your budget will help you get a lathe that meets your requirements while ensuring that you don't incur excessive costs.

References and Reviews

It is important to choose a reliable product and service provider by reviewing customer testimonials and product reviews about the lathe manufacturer or seller.

By considering all these factors, you can choose the most suitable CNC lathe for your needs and manage your production processes efficiently.

THINGS TO KNOW ABOUT CNC TURNING PROCESS

Some basic issues that should be known about CNC turning process are as follows:

Basic Principle of Turning Process

The turning process is based on the principle of rotating the workpiece and shaping the part by moving the cutting tool parallel to this rotational movement.

Selection of Cutting Tools

Depending on the type of material to be machined, the geometry of the workpiece and the desired result, it is important to select the right cutting tools. Different insert shapes and materials fulfil different machining requirements.

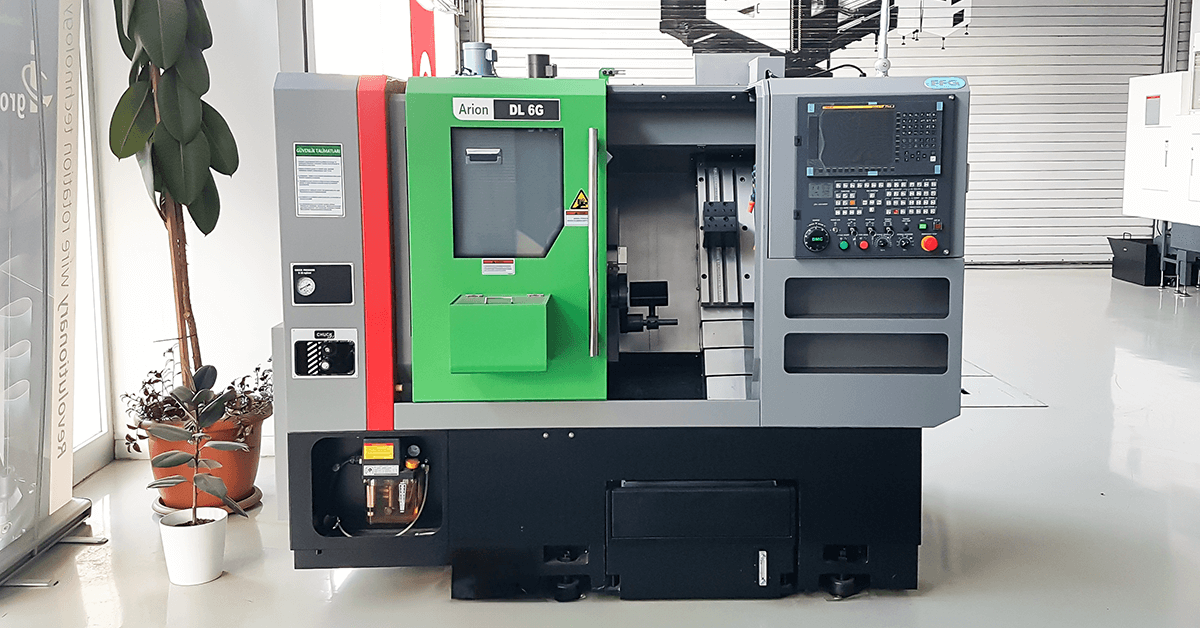

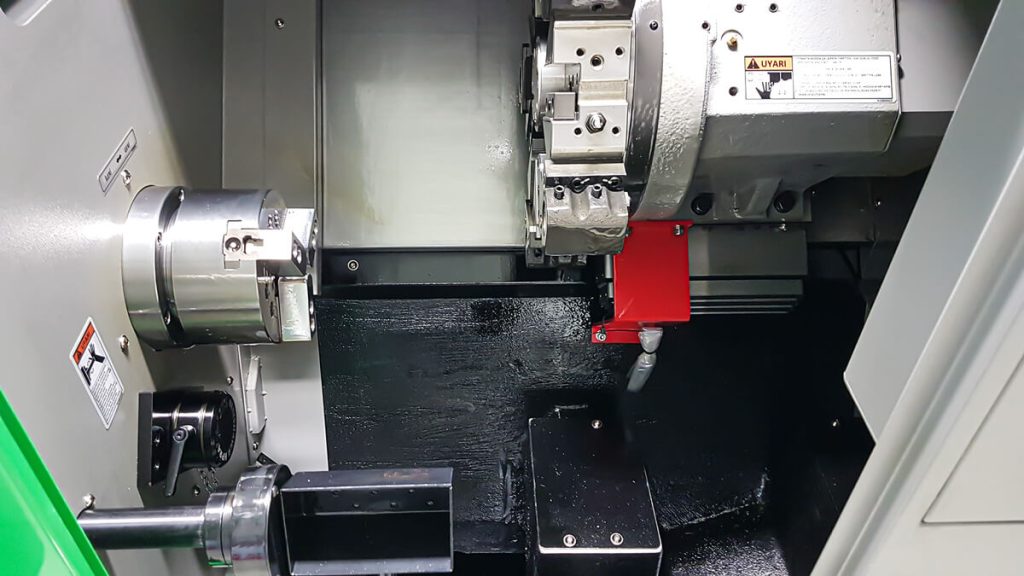

Parts of Lathe Machine

A CNC lathe consists of basic parts such as a spindle that rotates the workpiece, a tool tower or lathe barrel that carries the cutting tools, a drive mounted on a bed, and a control unit.

CNC Programming

In order to perform the turning process successfully, it is necessary to create a CNC programme containing the process steps. This programme specifies cutting paths, speeds, feed rates and other machining parameters.

Things to Consider During the Turning Process

There are many factors to be considered during the process, such as correct fixing of the workpiece, correct positioning of the cutting tools, determination of appropriate cutting speeds and feed rates, cooling and lubrication.

Precision and Quality Control

During and after the turning process, the dimensions, surface quality and other characteristics of the workpieces must be checked regularly. This ensures that the workpieces conform to the required tolerances and quality standards.

Safety Precautions

Appropriate safety precautions must be taken to ensure that the turning process is carried out safely. This includes measures to ensure the safety of the workpiece and the operator, such as covering cutting tools with protective shields, using suitable holders to secure the workpiece and training the operator.

This basic information provides a general understanding of the CNC turning process and covers some of the key topics that are important for the successful performance of the process.

DEVELOPMENT OF CNC LATHE FROM PAST TO PRESENT

The development of CNC lathes is closely related to the evolution of the modern manufacturing industry. Here are the important stages of CNC lathes from the past to the present;

First Lathes

The origins of the lathe process begin with mechanical benches powered by manpower or natural energy sources such as water and wind. These benches emerged as simple structures capable of machining stone or metal parts.

Industrial Revolution

In the 18th and 19th centuries, with the industrial revolution, the development of steam power and other machine technologies led to the evolution of the lathe process. More powerful and precise lathes appeared.

Beginning of Numerical Control

In the mid-20th century, with the development of computer technology, numerical control (CNC) technology emerged. This technology automated lathe operations controlled by a computer.

First CNC Lathes

In the 1950s and 1960s, the first CNC lathes appeared. These machines replaced mechanical control systems with numerical control systems.

Development of Computer Technology

With the rapid development of computer technology from the 1970s onwards, CNC lathes became more complex and powerful. Computers were used to control more process parameters.

Increased Sensitivity and Automation

In the following years, the precision and automation levels in CNC lathes increased. Automatic tool changing, part loading/unloading systems and other automation features became widespread.

Advanced Processing Technologies

In recent years, machining technologies and methods on CNC lathes have become increasingly advanced. Innovations such as high-speed machining, multi-axis machining and advanced material processing techniques have improved the performance of the machines.

Today, CNC lathes are important tools widely used in the manufacturing industry. With ever-evolving technologies, they continue to become even more precise, fast and efficient.

Computer Controlled Processing

Computer Controlled Processing